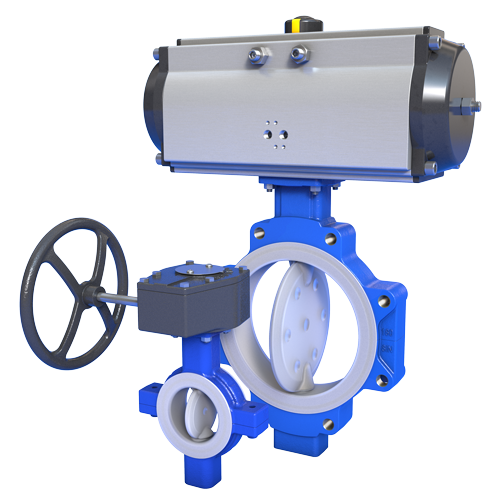

Product Description

- Fully PFA lined disc and body provide unsurpassed resistance to corrosion, permeation and microbial contamination for maximum purity and reliability with minimum maintenance.

- Durable, spherically molded PFA liner and matching disc interface to form a tight bidirectional seal.

- Full width 360° energized backup liner provides uniform sealing.

- AcrisealTM live-loaded, stem sealing system self-adjusts to eliminate leak paths and reduce fugitive emissions for long-term, maintenance-free operation. (ISO 15848-1 compliant)

- Extended PFA liner forms a protective sleeve shielding the stem from corrosive media and eliminating leak paths.

- PFA disc over-molding is mechanically bonded to the base metal for full vacuum capability.

- Streamlined disc engineered for maximum flow.

- High-strength one-piece 17-4 stainless steel disc and stem standard for improved reliability.

- Energized flange seals maintain proper sealing between valve and flange.

High Performance PFA* Lining

- Melt processable for precise molding of parts with smoother surface finishes than PTFE liners.

- Superior flexibility to withstand repeated flexing and dynamic loads for extended service life.

- Higher resistance to permeation for increased durability with lower total cost of ownership.

- Lower particle shedding for maximum purity.

- Superior creep resistance at high temperatures.

- Increased resistance to microbial contamination.

*PFA is also known by the trade name Teflon®.

AcrisealTM Stem Sealing System

Precision engineered for reliable, maintenance-free service, the AcrisealTM three step stem sealing system provides unmatched sealing for long term zero leakage performance. The primary seal is created by the spherically molded PFA body liner and matching disc hub interface. The energized backup liner maintains tight contact pressure for consistent shutoff in high cycle applications. An independent secondary seal is formed by the extended body and disc liners. The flexible PFA body liner extends into the stem cavity and the disc liner envelops the stem. The resulting protective sleeve eliminates potential leak paths for fugitive emissions and shields internal components from contact with the media. This feature works in conjunction with the tertiary safety seal to ensure compliance with ISO 15848-1 standards for fugitive emissions.

Precision engineered for reliable, maintenance-free service, the AcrisealTM three step stem sealing system provides unmatched sealing for long term zero leakage performance. The primary seal is created by the spherically molded PFA body liner and matching disc hub interface. The energized backup liner maintains tight contact pressure for consistent shutoff in high cycle applications. An independent secondary seal is formed by the extended body and disc liners. The flexible PFA body liner extends into the stem cavity and the disc liner envelops the stem. The resulting protective sleeve eliminates potential leak paths for fugitive emissions and shields internal components from contact with the media. This feature works in conjunction with the tertiary safety seal to ensure compliance with ISO 15848-1 standards for fugitive emissions.

The third sealing mechanism in the AcrisealTM stem sealing system is a graphite filled PTFE safety seal. Completely isolated from the process media by the extended disc liner and energized by a coil spring, the safety seal self-adjusts for changes in temperature and wear to ensure absolute zero leakage shutoff of corrosive and ultra pure process media.

End of Line Service

The wide elastomer backup liner rests in a machined body groove enabling downstream dismantling at full working pressure. This unique feature makes Acris ideal for end of line service.